Date: 2026-03-05 Page is: DBtxt003.php txt00027244

AIRCRAFT ENGINES

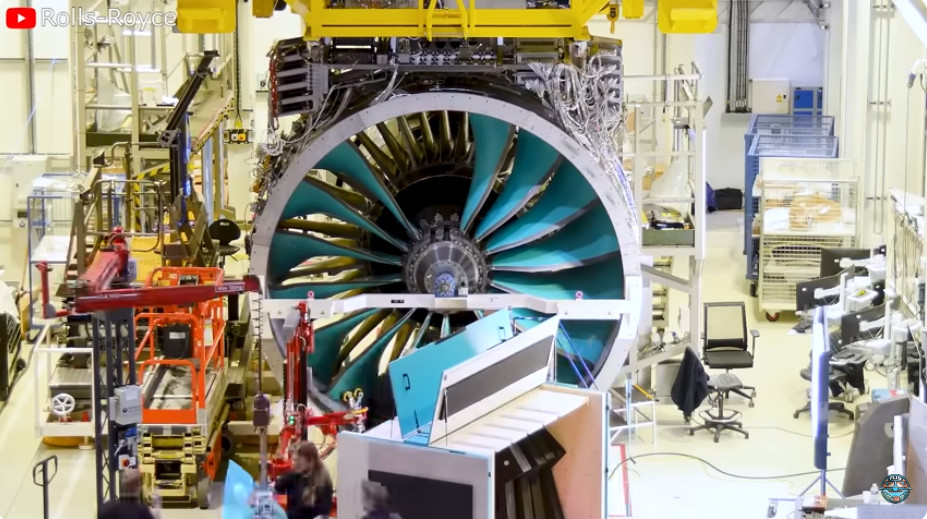

NEW CFM Rise and ROLLS ROYCE Ultra-Fan

FLIG AVIA: These Two 'NEW MASSIVE Engines' Will Change Aviation Forever! Here's Why

NEW CFM Rise and ROLLS ROYCE Ultra-Fan

FLIG AVIA: These Two 'NEW MASSIVE Engines' Will Change Aviation Forever! Here's Why

Original article: https://www.youtube.com/watch?v=jcvqc93fT2M

Peter Burgess COMMENTARY

Peter Burgess

FLIG AVIA

Jun 21, 2024

11.1K subscribers ... 115,918 views ... 3.3K likes

UNITED STATES

These Two 'NEW MASSIVE Engines' Will Change Aviation Forever! Here's Why

- Intro 00:00 - 00:49

- CFM RISE 00:49 - 04:00

- Rolls Royce Ultrafan 04:00 - 06:13

- How engines are made 06:13 - 09:47

- Aircraft engine market 09:47 - 10:53

These Two 'NEW MASSIVE Engines' Will Change Aviation Forever! Here's Why

In the competitive landscape of commercial aviation, the engine has been a pivotal factor, with manufacturers updating engines to keep older aircraft designs viable. Notably, Boeing's 737 NG and Max series have extended the model's lifespan to over 57 years, and Airbus's Neo series has achieved success by modernizing engines for enhanced efficiency. The ingenuity of some engines is such that they have been recognized with Guinness World Records.Yet, achieving a world record does not assure that an engine will be enough to make a transformation in the history of aviation. But with nowadays development, there are actually such engines. Find out in this episode of Flig Avia: What are these engines? How are they made? And Why are they changing the industry?

CFM RISE

The first to mention should be the CFM Rise Revolutionary Innovation for Sustainable Engines. This initiative is a collaborative venture between Safran Aircraft Engines of France and G E Aerospace. The project was launched by CFM in June 20 21 and the goal of the partnership is to develop an engine compatible with sustainable aviation fuels and hydrogen, aiming to decrease CO2 emissions and fuel usage by 20 percent. To understand the importance of the CFM RISE Engine, it's crucial to briefly review the evolution of aircraft engines.

Jet engines have undergone a remarkable transformation from their simple beginnings to the advanced turbofan engines of today, which boast high bypass ratios for enhanced performance. However, the quest for efficiency has led to heavier engines due to increased fan diameters. To address this, the industry has explored alternative designs like unducted fan engines, which efficiently move larger air masses. Historical attempts at such designs, like the Pratt & Whitney Allison 578-Delta X-ray and the General Electric GE36, showcased the potential for fuel savings and operational efficiency. Despite their innovative features, these engines were not pursued further due to challenges such as noise levels and mechanical complexities.

Transcript

Intro.

- 0:00

- in the competitive landscape of

- commercial Aviation the engine has been

- a pivotal factor with manufacturers

- updating engines to keep older aircraft

- designs viable notably Boeing's 737

- nanograms and Max series have extended

- the model's lifespan to over 57 years

- and airbus's Neo Series has achieved

- success by modernizing engines for

- enhanced efficiency the Ingenuity of

- some engines is such that they have been

- recognized with Guinness World Records

- yet achieving a world record does not

- assure that an engine will will be

- enough to make a transformation in the

- history of Aviation but with nowadays

- development there are actually such

- engines find out in this episode of

- Flavia what are these engines how are

- they made and why are they changing the

- industry but before we start please hit

- the Subscribe button if you haven't

- already so you'll be the first to see

- our next videos now let's dive in the

- CFM RISE.

- first to mention should be the CFM rise

- revolutionary Innovation for sustainable

- engines this initiative is a

- collaborative venture between saffron

- aircraft engines of France and GE

- Aerospace the project was launched by

- 1:01

- CFM in June 20th 21 and the goal of the

- partnership is to develop an engine

- compatible with sustainable Aviation

- fuels and hydrogen aiming to decrease

- CO2 emissions and fuel usage by 20% to

- understand the importance of the CFM

- rise engine it's crucial to briefly

- review the evolution of aircraft engines

- jet engines have undergone a remarkable

- transformation from their simple

- Beginnings to the advanced turbofan

- engines of today which boast High bypass

- ratios for enhanced performance however

- the Quest for efficiency has led to

- heavier engines due to increased fan

- diameters to address this the industry

- has explored alternative designs like

- unducted fan engines which efficiently

- move larger air masses historical

- attempts at such designs like the Pratt

- and Whitney Allison 578 Delta X-ray and

- the General Electric G36 showcase the

- potential for fuel savings and

- operational efficiency despite their

- Innovative features these engines were

- not pursued further due to challenges

- such as noise levels and and mechanical

- 2:00

- complexities but fortunately despite the

- setbacks faced in the past the aviation

- industry has seen a Resurgence of

- interest in open rotor engines thanks to

- the latest breakthroughs in Material

- Science design techniques and

- computational advancements these

- developments have made the CFM rise

- engine not just a possibility but a

- highly sought-after Innovation saffron

- has taken the lead in this revival

- successfully developing an open rotor

- engine that matches the quietness of

- modern turbo fans a remarkable

- achievement the engine tested

- extensively in 2017 and 2019 mirrors the

- G36 unducted fan in appearance but

- stands apart with its gearbox controlled

- counter rotating fans achieving noise

- levels comparable to the latest CFM leap

- engines additionally in a collaborative

- effort General Electric has refined the

- design further transitioning to a single

- fan system with adjustable Stater veins

- for enhanced airf flow management this

- streamlined gearbox design reminiscent

- of those in turboprop engines not only

- simplifies the engine's mechanics but

- 3:00

- also holds the promise of additional

- noise reduction marking a pivotal

- development in the CFM rise engine's

- Journey the CFM rise stands out with its

- 13 ft rotor diameter setting it apart

- from its predecessors and other

- traditional turbo props its core is more

- compact compared to the G36 the design

- incorporates recuperators to reclaim

- energy lost through exhaust heat while

- it may resemble a conventional counter

- rotating engine it differs in that the

- second stage blades are stationary and

- the stators have an acve pitch for

- adjustable control these components

- serve as flow recovery veins enhancing

- the fan pressure ratio and managing

- rotor load a reduction gear set links

- the turbine and rotor CFM will employ a

- three axle weaving technique to create

- the carbon fiber composite blades for

- these engines the engine's hot section

- will feature ceramic Matrix composits

- and advanced metal alloys by integrating

- a hybrid Electric System the engine is

- poised to cut fuel consumption by 20%

- marking a significant advancement in

- aviation Tech technology the second one

- Rolls Royce Ultrafan.

- 4:01

- is the ultra fan of Rolls-Royce it was

- unveiled in 2014 and initially served as

- a new engine concept and a testbed for

- new technologies due to low interest in

- large gas turbines from aircraft

- manufacturers testing began in early

- 2023 at testbed 80 the world's largest

- Aero engine testing facility using 100%

- sustainable aviation fuel Rolls-Royce

- CEO tufon urgen bilgic described the

- ultrafan demonstrator as a

- transformative technology for for both

- current and future engines notably the

- ultrafan has a massive 140 in diameter

- making it the largest jet engine

- surpassing the ge9x is 135 in the

- ultrafan design focuses on improving

- efficiency reducing emissions and

- enhancing performance it features a high

- bypass ratio of approximately 15 to1

- achieved through a large fan and a

- relatively small Core Design This High

- bypass ratio results in a quieter and

- more efficient engine additionally the

- ultra fan includes a power gearbox that

- 5:01

- allows the fan to rotate at an optimal

- speed different from the core delivering

- an aerospace power record of 64 megawatt

- during testing carbon titanium fan

- blades stronger and lighter than

- traditional metal blades further improve

- performance by withstanding High loads

- and temperatures while resisting

- corrosion and fatigue the lean burn

- combuster also contributes to lower fuel

- consumption and Emissions the ultrafan

- offers substantial benefits in terms of

- sustainability and adaptability it is

- 25% more efficient than the first

- generation Trent engine potentially

- saving up to 20% of fuel per flight

- compared to current engines emissions

- reductions include nearly 40% less

- nitrogen oxide and 35% less noise than

- Trent engines with virtually no

- nonvolatile particulate matter with a

- Thrust range from 25,000 to over 100,000

- lb the ultrafan can power a wide variety

- of aircraft making it particularly

- significant for Rolls-Royce as they aim

- to strengthen their position in the

- narrow body Market the ultrafan f

- futureproof design capable of operating

- 6:01

- on 100% sustainable aviation fuel

- ensures its relevance and superiority

- over other Market leading engines like

- the ge9x PW 1100 gjm and leap 1A so how

- How engines are made.

- are these engines designed when it comes

- to crafting engines for colossal

- aircraft weighing 200 tons the design

- process is intricate and must receive

- official approval prior to assembly

- engineering teams within companies are

- extensive tasked with meeting the

- detailed demands of their clients making

- this the most costly and time intensive

- stage in engine creation the Rolls-Royce

- Trent xwb engine for example underwent a

- six-year design and construction phase

- initiated in 2004 when Airbus sought a

- new engine for the a350 by 2006

- rollsroyce was selected to fulfill this

- need and in 2010 the a350 powered by two

- Trent xwb engines took flight

- rolls-royce's Derby facility in the UK

- is a hub for jet engine assembly where

- the complex process is routine for the

- 7:00

- workforce here a new $35 million engine

- is produced every 20 days starting with

- the fan disc a robust component that

- secures all 22 blades each is finely

- honed as a chef's knife for efficient

- air movement expert workers install

- these prefabricated blades and insert

- annulus fillers between them to optimize

- air flow completing the fan assembly a

- key part of the xwb the engine's fan is

- positioned at the front with the turbine

- and shaft at the rear driving the fan

- the low press turbine is is vertically

- mounted at the engine's rear and the

- core is constructed piece by piece

- concurrently the fan is moved to another

- area for casing assembly a detailed task

- involving numerous wires and pipes as

- the core is completed it's aligned with

- the fan and case ensuring a perfect fit

- as this occurs another group finalizes

- the core assembly starting from the

- compressor and working upwards to the

- combuster and turbines they have to work

- fast because the assembly floor moves up

- as the engine comes together after the

- engine core is fully put together it's

- time to attach it to the fan and it's

- housing the core is laid out flat and a

- 8:01

- rotating mechanism ensures that the fan

- blades fit snugly into their housing

- behind the massive fan 68 turbine blades

- work together each with a power of four

- cars cumulatively surpassing the output

- of 300 cars although it takes 20 days to

- assemble the engine it's not ready for

- shipment until it passes rigorous

- testing Rolls-Royce conducts these tests

- in a special control room where the

- engine is tested on a rig and the

- operator acts as a pilot but only after

- all safety locks are Eng engaged to

- prevent entry during operation each test

- is meticulously recorded to confirm the

- engine meets every customer

- specification the testing area is

- designed to isolate noise allowing the

- control room to remain quiet there are

- three main types of tests pass-off tests

- to verify performance standards research

- tests and development tests where the

- most intense evaluations occur these

- include a fan blade off test to check

- containment water ingestion tests to

- simulate Heavy Rain Bird strike tests

- and cold start tests to assess

- performance in in freezing conditions

- 9:00

- once the engine clears all tests it's

- ready to be shipped usually on a flatbed

- trailer but sometimes by cargo ship or

- even an aircraft like the Airbus Beluga

- for Urgent deliveries at the assembly

- facility such as the one in too for the

- Airbus a 350 the engines are mounted

- onto the aircraft at one of the final

- assembly stations Rolls-Royce and Airbus

- have a long-standing partnership

- ensuring the delivery of these efficient

- engines the Trent xwb engines weighing 8

- tons and costing 32 million each are

- carefully lifted by a hydraulic crane

- for mounting Precision is key as nearly

- 20,000 parts are assembled by hand and

- any error could be costly the engine is

- secured with 50,000 lb of thrust on the

- mounting brackets and once everything is

- double checked for security the aircraft

- is deemed ready for service in 2023 the

- Aircraft engine market.

- aircraft engine Market was estimated at

- 95.1 billion forcast suggest a surge to

- 87.26 billion within a decade with an

- annual growth rate of

- 10:00

- 7.92% this lucrative Market is dominated

- by four key players General Electric

- Aviation 16% Rolls-Royce holds 18% Pratt

- and Whitney command is significant 26%

- and CFM International leads with 39% of

- Global Production but recently the

- aviation industry is witnessing a shift

- as rolls-royce's new ultrafan with 140

- in in diameter which is 5% larger than

- General Electric's ge9x it aims to claim

- the title of the world's larg largest

- airplane engine while it awaits final

- testing General Electric retains the

- crown for the most powerful jet engine

- with the ge9x achieving a

- record-breaking

- 134,00 lb of thrust it remains to be

- seen if rolls-royce's Ultra fan will

- surpass G's record so which engines

- would you choose if you were an aircraft

- manufacturer please let us know in the

- comments section and don't forget to

- like and share the video If you enjoyed

- it