|

DMKD, Ukraine

Posted on 18/08/2014

DMKD, Ukraine

The steel plant in Dneprodzerzhinsk was founded in 1887 on the banks of Ukraine’s largest river the Dnepr supplied with coal from the Donezk bassin and iron ore from Krivoy Rog. The mill was nationalized in 1917 and named after Feliks Dzierżyński (Revolutionary and founder of the Sowjet secret police) in 1925.

Today the plant is privatized and runs four blast furnaces (No. 1/8/9/12) a BOF shop including two 250 ton top blown vessels. Two continuous casters and several rolling mills for railroad axles, rails, billets, tube blanks, medium sections and sheet pile.

Images now at Stahlseite.

DMKD Blast Furnaces

Posted in Works | Tagged Blast Furnace, DMKD, Dneprodzerzhinsk, Steel Mill, Ukraine | Leave a reply

----------------------------------------------------------

Piombino

Posted on 24/04/2014

© Uwe Niggemeier

After the remaining iron ore stocks at the Lucchini steel mill in Piombino, Italy were exhausted the company started to shut down blast furnace No. 4 last night. Chances are slim that it ever will be restarted.

Posted in Works | Tagged Blast Furnace, Italy, Lucchini, Piombino

----------------------------------------------------------

Four Queens

Posted on 19/04/2014

Scunthorpe Blast Furnaces

© Uwe Niggemeier

Victoria, Anne, Bess and Mary.

Further viewing at Stahlseite.

Tata Steel’s integrated steel plant in Scunthorpe, GB was founded in 1864 under the name Frodingham Iron Works.

Iron was produced from local iron ore deposits since 1865. A Thomas converter steel making shop started it’s production in 1890.

In 1912 Frodingham took over the nearby Appleby Iron Co. (founded in 1874) to form the Appleby Frodingham Steel Co.

This enterprise became part of the United Steel Companies in 1937. In 1939 two new large volume blast furnaces were installed (Mary & Bess). In 1954 Anne and Victoria were added to complete the “Four Queens”.

BOF Shop

© Uwe Niggemeier

In 1967 the United Steel Companies became part of the newly founded British Steel Corporation.

The Anchor project (1969-1973), one of the largest investments into the British steel industry ever, brought a new BOF shop, new rolling mills and the Immingham iron ore terminal by the Humber river.

British Steel merged with Koninklijke Hoogovens from the Netherlands to form Corus in 1999. Eigth years later Corus was taken over by the Tata Steel group from India.

Tata Scunthorpe today consists of 4 blast furnaces (three active) a BOF shop containing three 300 ton vessels, a slab caster, a bloom caster and three rolling mills (rails, heavy plate and wire).

Posted in Works | Tagged Blast Furnace, Great Britain, Scunthorpe, Steel Mill, Tata Steel

----------------------------------------------------------

No. 5 Is Down

Posted on 16/02/2014

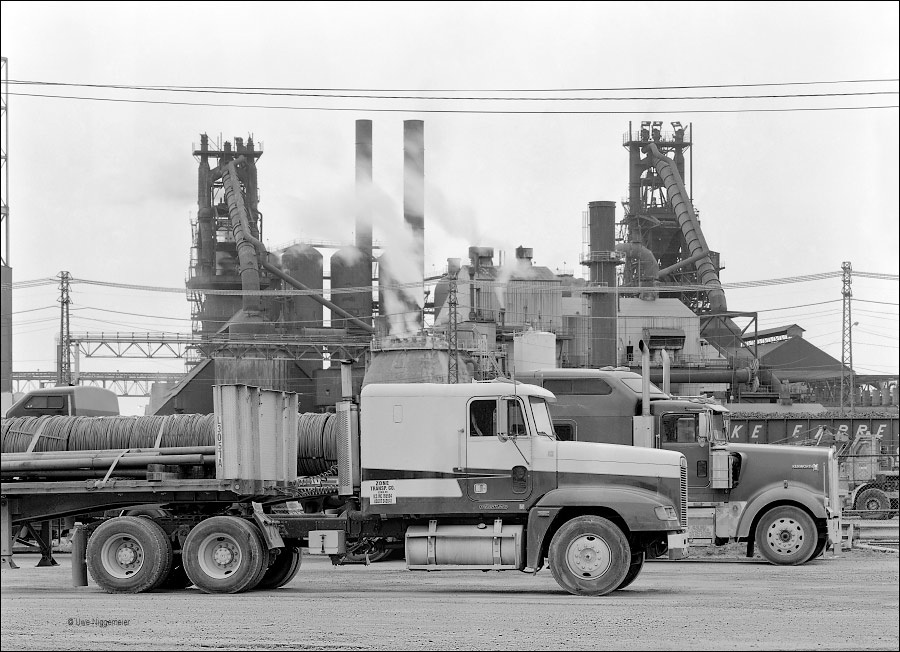

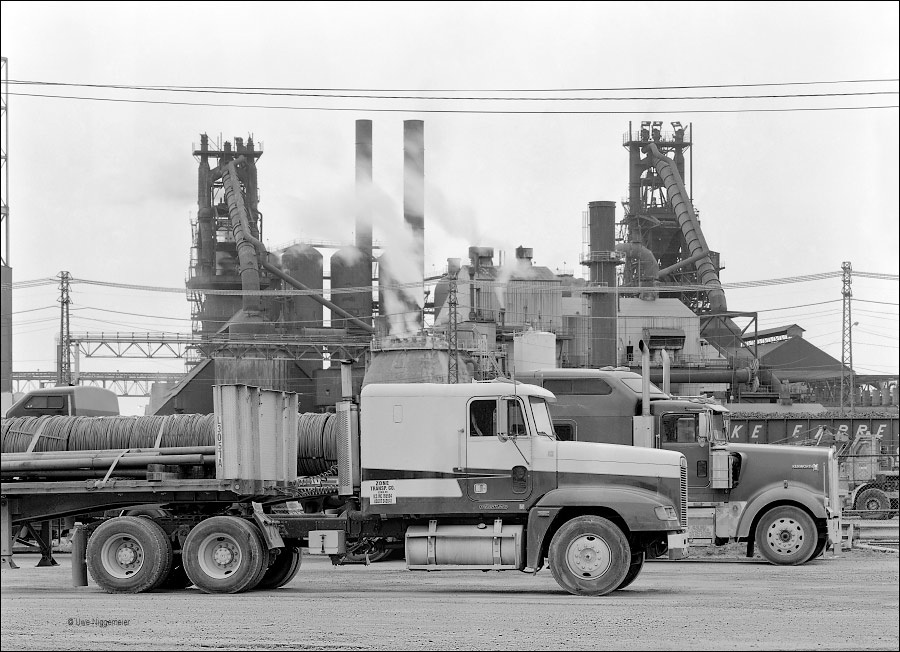

WP-Steel in 2004 © Uwe Niggemeier

Despite the harsh winter weather the demolition of RG Steel’s former Mingo Junction site in Ohio continues.

Blast furnace No. 3 was already dismantled in 2004. The remaining furnace No.5 five came down recently too.

The mill was idled in 2009 and still waits for a new investor to restart the electric arc furnace and the rolling mill.

Posted in News | Tagged Blast Furnace, Mingo Junction, Ohio, RG Steel, Wheeling Pittsburgh

----------------------------------------------------------

Replaced By An EAF

Posted on 27/11/2013

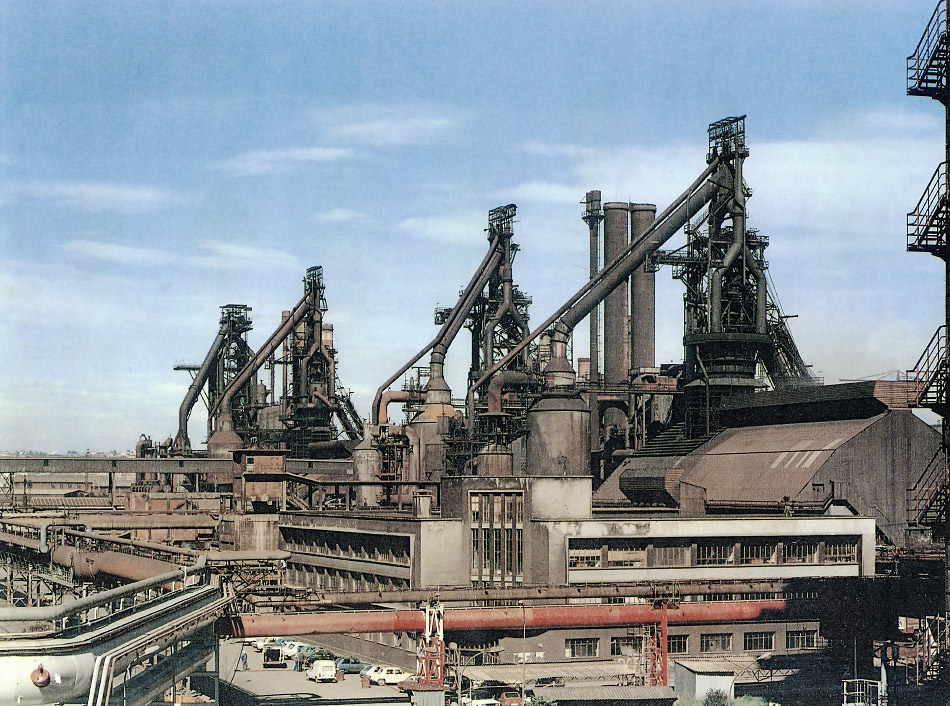

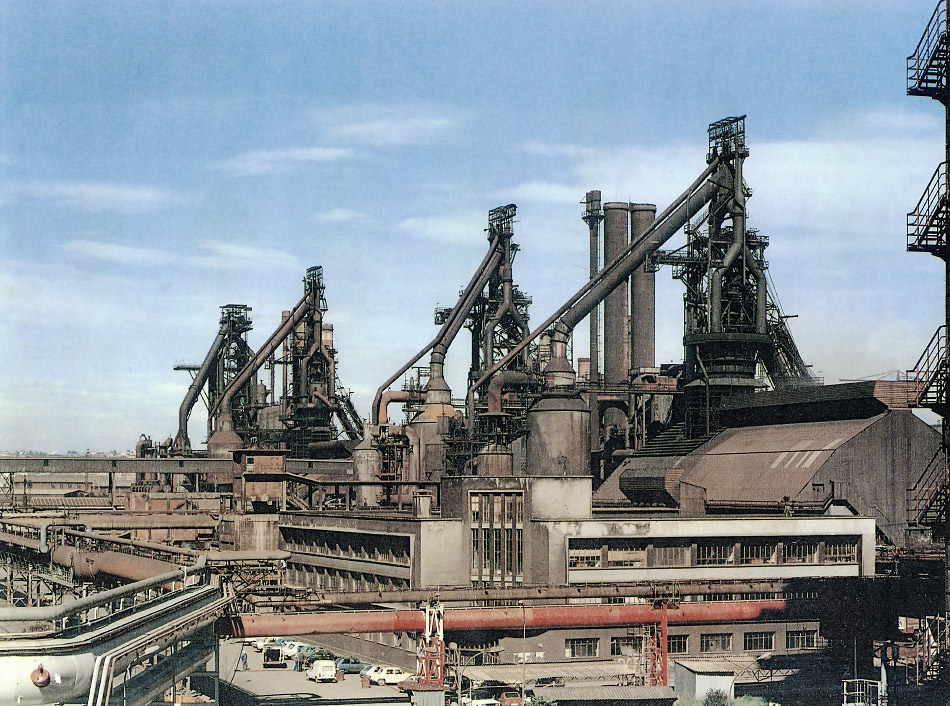

Loraine Blast Furnaces

The Republic Steel company just fired up it’s new electric arc furnace in Loraine, Ohio. It replaces two blast furnaces and a BOF steel making shop idled five years ago.

Blast furnace No. 3 has a hearth diameter of 8,68 meters, furnace No 4 is 8,83 meters wide.

The BOF shop was built in 1971 and it contains two 220 ton vessels.

Posted in Gallery, News, Works | Tagged Blast Furnace, Lorain, Ohio, Republic Steel, USA | Leave a reply

----------------------------------------------------------

Vintage Image #10

Posted on 16/10/2013

Rodange 1975

The blast furnaces of S.A. Métallurgique et Minière de Rodange-Athus (MMRA) in Rodange, Luxemburg and the the ropeway that connected them to the iron ore mine Doihl.

Both were closed in 1978. Two rolling mills still exist here.

Posted in Works | Tagged Blast Furnace, Luxembourg, Rodange, Ropeway | 2 Replies

----------------------------------------------------------

Vintage Image #9

Posted on 30/08/2013

Aviles Blast Furnaces

Blast furnaces Carmen (named after Carmen Polo, Franco’s wife), Joaquina, Rosario and Carmen IV in Aviles, Spain. Later called blast furnaces 1-4.

The furnaces were built in between 1957 and 1969 by the public enterprise ENSIDESA (Empresa Nacional Siderúrgica Sociedad Anónima). Hearth diameter was 8,69-8,99 meter.

Furnace 1&2 were shut down in1989 and furnaces 3&4 in the mid 1990ies after the hot metal production was translocated to the newer furnaces in Gijon.

By 2001 all furnaces were dismantled.

Blast Furnaces Aceralia

Posted in Historical, Works | Tagged Aceralia, Aviles, Blast Furnace, Ensidesa, Spain | 3 Replies

----------------------------------------------------------

Steubenville

Posted on 10/08/2013

Steubenville

Gone.

Posted in Gallery, Historical, Works | Tagged Blast Furnace, Steubenville, USA, Wheeling Pittsburgh | 1 Reply

----------------------------------------------------------

Longwy

Posted on 10/08/2013

Longwy

In the 1960ies the small town of Longwy, France (pop. 60000) still housed more than 20 blast furnaces. A unique density.

The mills were running on local iron ores of a rather poor quality that became uneconomical in the 1970ies with high quality iron ore shipped into Europe from overseas.

35 years ago, after the announcment of La Chiers’ closure, Longwy’s steel workers started their long and exceptional violent struggle to keep their jobs.

Since the closure of Arcelor’s wire rolling mill in 1998 there is no more steel industry in town.

Jean-Marie Ottelé site: www.industrie.lu is a unique source of information about the Terre Rouge (Red Earth) steel industry.

Longwy Map

1: Cockerill-Ougrée-Providence

Founded: 1865.

Closed: 1987

2: Lorraine-Escaut

Founded 1835 Closed 1987

3: Hauts Fourneaux De La Chiers

Founded: 1881 Closed: 1979

4: Aciéries de Longwy

Founded: 1880 Closed: 1978

5: Hauts-Fourneaux Réunis de Saulnes et Uckange

Founded: 1872 Closed: 1991

Posted in Historical, Works | Tagged ArcelorMittal, Blast Furnace, France, Longwy, Usinor | 1 Reply

----------------------------------------------------------

California Furnaces

Posted on 25/07/2013

Kaiser Steel

The least thing one would expect more than 2000 miles west of the rustbelt and just 50 miles out of Hollywood is a fully integrated steel mill.

But it was there, built in 1942 by Henry J. Kaiser on a former hog farm and ,mostly ,dismantled in the late 1980ies.

In the early 1940ies Kaiser Industries were in search for a steel plate supply for their nearby Richmond shipyards where more than 700 vessels, mostly “Liberty Ships” were built during WWII.

In 1942 ground was broken in Fontana and by 1943 a coking plant, one blast furnace (“Big Bess”) with a capacity of 1200 tons/d and an open hearth shop were under fire.

A 148″ plate mill was added in 1943 and the 86″ hot strip mill started in 1950.

In it’s heyday the mill ran four blast furnaces(hearth diameter 8,7 -8,9 meter) and installed the second BOF steel making shop in the U.S. as early as 1955.

In the 1960ies the location 50 miles away from the coast (imposed by the U.S. Army) at the so called “Inland Empire” became an increasing problem with all raw materials having to be hauled in by rail.

In a last attempt to make the plant competitive a new BOF shop and a continuous caster were built in 1978 to be closed down for good already in October 1983.

Kaiser Steel filed bancruptcy and the plate and hot strip rolling mills were taken over by California Steel Industries in 1984, supplied with slabs from overseas.

The plate mill was sold to the Oregon Steel Company in 1989 and abandoned in 1994.The 86″ hot strip mill is still active.

The remaining iron and steel making facilities were occasionally used by nearby Hollywood studios as a film set (Terminator2) and later dismantled.

The BOF shop was bought by the Capital Iron & Steel Co and shipped to China in 1993.

The ground is now overbuild by a car race track.

:)

|